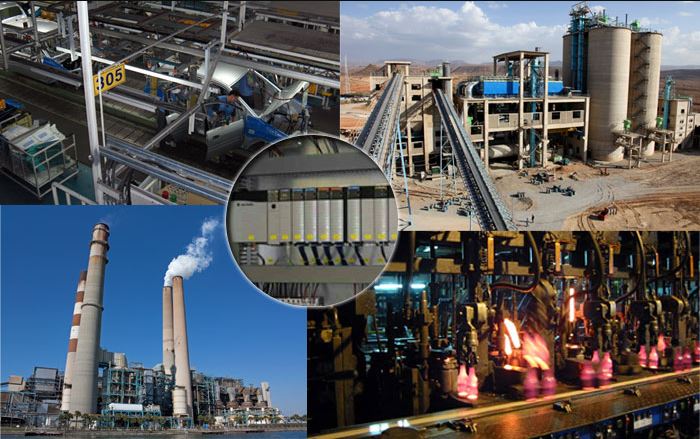

For over four decades now, the #Programmable Logic Controllers (PLC) system have continuously performed a notable task in automated control process in #manufacturing industrial operations. In fact, PLC serves as the #intelligence of an automation system to carry out manufacturing tasks and deliver highly reliable control of industrial automation processes. PLC offers numerous command functions, mathematical activities, many applications (industrial, domestic, #commercial & education), and benefits to create flexibility & efficient #manufacturing industrial environments.

Major Areas of Application of PLC

PLC operates effectively in the implementation of numerous industrial automation control processes where the relay control system won’t work accurately. The major Industries where PLCs are used for the day to day control of industrial tasks include;

-

Automobile industry

-

Cement Industry

-

Chemical industry

-

Glass Industry

-

Food Processing System

-

Paper industry

-

Plastic Industries

-

Paint Industries

-

Pharmaceuticals Process

-

Robotic Automation System

-

Steel Industry

-

Textile industry

-

Oil and Gas Power Plant

-

Oil & Gas Processing

-

Water Treatment Systems

-

Wind Turbine System

-

Underground Coal Mine and many more!

Applications of PLC in the different Sector day to day activities

The popular usage of PLC in different sectors to carry out numerous control process tasks include;

-

Applications of PLC in Industrial Sectors

-

Applications of PLC in Commercial Sectors

-

Applications of PLC in Power Station Sectors

-

Applications of PLC in Domestic Sectors

-

Applications of PLC in Education Sectors

Applications of PLC in Industrial Sectors

Considering the implementation of industrial automation for industrial processes, PLCs are useful in a wide variety of industrial automated complex control systems ranging from manufacturing production, process control functions, building the system, monitoring machine tool process or equipment. The outline below are some of the typical Applications of PLC in Industrial Sectors include;

-

Automatic Bottle or Liquid #Filling System.

-

Automatic Drainage Water Pump Monitoring & Controlling System.

-

Conveyor Belt System controls implement with Sequence & Interlocking procedure.

-

Control of Transportation systems such as the Escalator system, Conveyor Belt System, and Elevator.

-

Controlling the Purging Procedure in Oil and Gas Industries

-

Energy Management System in control systems such as Boiler, Ball Milling, Coal Kiln, Shaft Kiln, etc.

-

Fault Detection & Protection of Industrial Machines such as three-phase ElectricMotors.

-

Glass production and recording data in Glass Industries

-

Industrial Crane Control System for Operation of Overhead Traveling Crane.

-

Manufacturing or Mixing the right quality and quantities of raw materials, and accuracy of data regarding Cement Industries.

-

Monitor and Regulating of Valve Switching In Oil, and Gas an Automation Power Plant

-

Packing and Labeling System in industries like Food & Beverage, Pharma, etc.

-

Paper Industries for the production of Pages, Books or Newspapers, etc

-

Time and Count-based Control System for an Industrial Machine.

-

Temperature Controller or Humidity by using the Sensors technology & PLC system.

-

Wind Turbine System for Maximum Efficiency, Recording Data, and Safety Purposes.

-

Real-time analysis of Underground Coal Mine or Water Level Sensing and Data Survey.

Applications of PLC in Commercial Sectors

The usage of PLC in the commercial sectors for control applications is increasing greatly. With the implementation of PLC, the commercial control system can easily be fully automated meaning without or with very minimal man intervention or requiring any tedious physical effort. The outline below are the control application where PLC can be used in the commercial sectors including;

-

Automatic Machine Handling System.

-

Automatic Car Washer System

-

Automated Guided Vehicle System.

-

Automation Control System for Well Drainage System.

-

Fire Detection and Alarm Control System.

-

Pressure Controller in Multi-Motor Pump Applications.

-

Mining Equipment Line Detection and Remote Control System.

-

Water and Waste management systems.

-

Sequence or Numerical Counting and Packing System.

-

Smart Traffic Control Signal System.

-

Smart Elevator Control System.

-

Luggage Handling Control System

PhotoCredit: program-plc.blogspot