MTW Wire

MTW denotes "Machine Tool Wire"

Description:

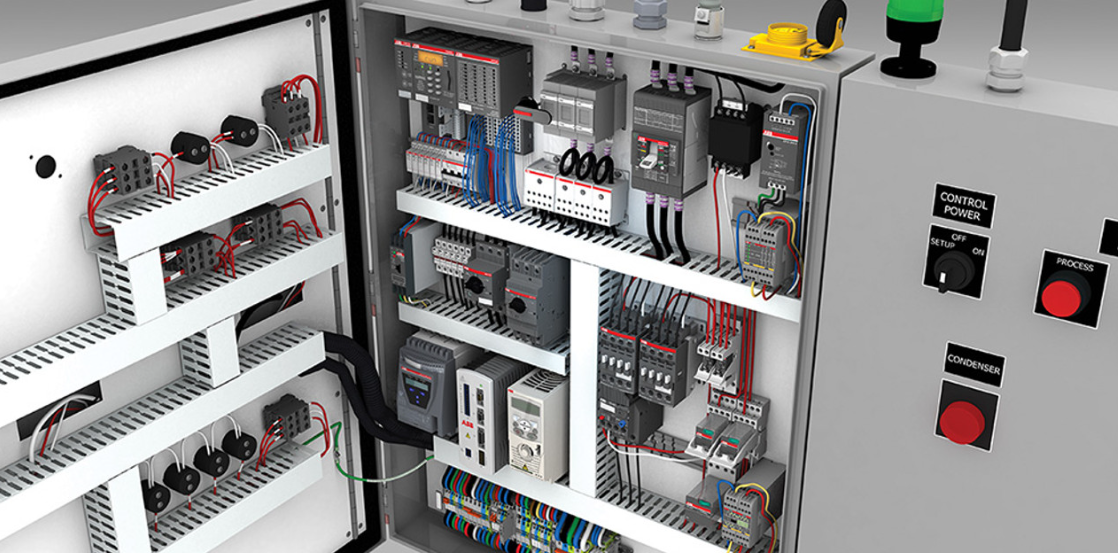

MTW (Machine Tool Wire) is a high-flexibility wire designed for use in environments where machinery and equipment need reliable, durable, and versatile wiring. Its stranded copper construction makes it particularly suitable for applications requiring frequent bending or movement (e.g Industrial Control panel). Further, MTW wire is insulated with PVC, providing resistance to moisture, oil, and other environmental hazards, making it a strong choice for industrial settings.

Key Characteristics of MTW

-

Primary Use: Ideal for wiring in machine tools, appliances, and control cabinets.

-

Construction: Made from stranded bare or tinned copper for flexibility and corrosion resistance.

-

Flexibility: High strand count provides greater flexibility than THHN wire, making it easier to install in tight spaces.

-

Insulation: Insulated with Polyvinyl Chloride (PVC).

-

Voltage and Temperature Ratings: Rated for 600V with a maximum operating temperature of 105°C.

-

Standards and Certifications: Passes the VW-1 Flame Test and complies with UL AWM styles (e.g., 1015, 1028, 1283, and 1284).

-

Additional Information: Often double-listed as MTW/TEW wire and available in flexible strand configurations, especially in #10, #12, and #14 AWG.

Application Benefits:

Flexibility: MTW's high strand count provides excellent flexibility, simplifying installation in tight or confined spaces, especially around machinery. Durability in Industrial Environments: With its resistance to moisture, oil, and heat, MTW wire can withstand harsh industrial conditions, enhancing reliability. Corrosion Resistance: Tinned copper versions offer additional corrosion protection, which prolongs the wire’s lifespan in damp or corrosive environments. Control Panels: MTW’s flexibility and insulation make it a preferred choice for wiring in control cabinets and panels, where it’s essential for wire to move easily and adapt to intricate setups. Safety Compliance: MTW wire meets strict safety standards, including the VW-1 Flame Test and UL AWM requirements, ensuring safe performance under challenging conditions.

THHN Wire

THHN Wire stands for "Thermoplastic High Heat-Resistant Nylon"

Description:

THHN (Thermoplastic High Heat-Resistant Nylon) is a robust building wire commonly used for electrical distribution in residential, commercial, and industrial settings. The wire features PVC insulation and a nylon jacket, providing excellent durability and resistance to heat and abrasion. THHN wire is frequently dual-rated as THWN, allowing for Outdoor or Wet-Location installations and enhancing its versatility as a building wire.

Key Characteristics:

-

Primary Use: Standard building wire for electrical systems in residential, commercial, and industrial environments.

-

Construction: Bare copper or aluminum conductor with thermoplastic (PVC) insulation and a protective nylon jacket.

-

Flexibility: Less flexible than MTW due to its nylon coating; can be stiff and challenging to install in confined spaces.

-

Temperature Ratings: Rated up to 90°C in dry locations and 75°C in wet locations.

-

Voltage Rating: Rated for 600V.

-

Water Resistance: Performs better in wet conditions; THHN is often dual-rated as THHN/THWN for added water resistance.

-

Dual Listing: Commonly listed as THHN/THWN, making it versatile for various environmental conditions.

Application Benefits:

Versatility in Building Wiring: THHN is widely used in electrical systems in residential, commercial, and industrial buildings due to its reliable performance in various conditions. Heat and Abrasion Resistance: THHN’s high heat tolerance (up to 90°C in dry environments) and durable nylon jacket make it resistant to wear and tear, even in exposed areas. Suitable for Wet Locations: With the THWN rating, THHN is appropriate for use in wet or outdoor conditions, offering added water resistance. Material Choices: Available in both bare copper and aluminum options, THHN allows for cost-effective installations, especially in large-scale projects where aluminum may be preferred for its lower weight and cost. Ease of Installation for Large Projects: THHN’s standard build and broad availability make it a go-to choice for large electrical projects, reducing installation time and cost.

Comparison Table: MTW vs. THHN |

||

Feature |

MTW |

THHN |

Denotes |

Machine Tool Wire |

Thermoplastic High Heat-Resistant Nylon |

Primary Use |

Machine tools, appliances, control cabinets |

Building wire for general electrical systems |

Conductor Material |

Bare or tinned copper |

Bare copper or aluminum |

Flexibility |

Highly flexible due to stranded construction |

Less flexible, can be stiff due to nylon jacket/coating, stiffer to install |

Insulation |

PVC (Polyvinyl Chloride) with excellent flexibility and moisture resistance |

PVC with a durable nylon jacket |

Voltage Rating |

600V |

600V |

Temperature Range |

Up to 105°C |

90°C in dry locations, 75°C wet locations |

Water Resistance |

Moderate resistance to moisture and oil |

Better water resistance, especially with THWN rating |

Typical Applications |

Control panels, machinery, industrial equipment |

Building wiring for indoor and outdoor use |

Standards |

VW-1 Flame Test, UL AWM styles |

Often dual-rated as THHN/THWN |

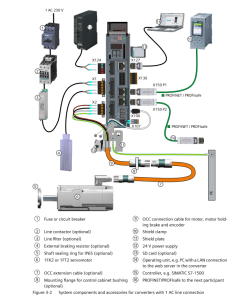

Image credit: Automationdistribution