The acronym PLCs denotes Programmable Logic Controllers. PLCs refer to the industrial digital computers that are designed for that control processes implemented using numerous manufacturing equipment including industrial robots, escalators, and assembly lines.Meanwhile, these sophisticated devices are used to control industrial production processes controls, flexible programming, and ease of troubleshooting is of great importance.

PLCs as industrial Controllers

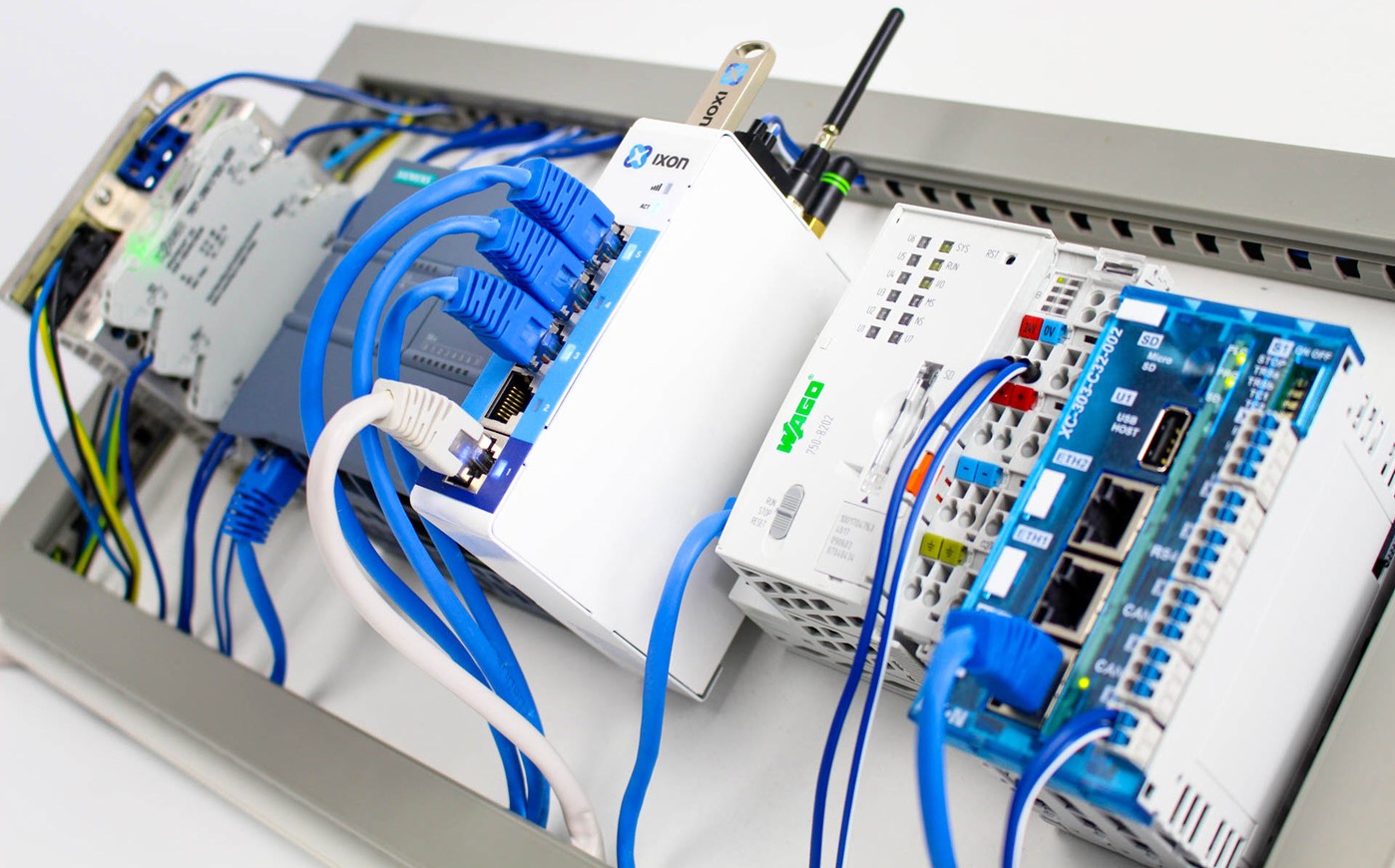

The application of PLC as an industrial digital controller increases in several industries to control processes where precision with zero error is vital.

Industrial controllers were introduced many decades ago and before that, manufacturers relied on cam timers, #electromagnetic relays, and other similar kinds of control devices to streamline their manufacturing processes. The #automotive industry used computer-controlled systems for the replacement of cam timers as well as hard-wired relays.

Industries implement several applications ranging from small production systems to large Control processing plants. Presently, computer-driven tools have become an essential part of industrial process control and factory automation.

Manufacturing industries need a variety of industrial controllers and equipment in order to produce high-quality products and make them beneficial for the end-users. Compared to PCs, PLCs are capable of working efficiently in harsh industrial environments where humidity, dust, temperature, mechanical shocks, and other hazards are predominant.

PLCs have in-built timers and counters which makes it easy for all the equipment or devices used to control industrial processes in the facility to be organized in time intervals and carry-out counting as well. A typical example is the automobile industry where one device or a set of devices works on painting car exterior while others are working on the engine parts.

One of the functions of an industrial digital computer is to set the specific time frame for machines so that all the processes can be performed in a perfectly harmonious manner.

Some of the advantages of PLC include:

Cost-effectiveness

Accuracy and dependability

Low power consumption

Higher flexibility and integration

Ease of maintenance and installation

The rapid advancement in automation technology has made it possible for industries to experience high productivity, effective high-quality products at affordable costs and at large scales.

Essentially, Powerful industrial controllers, robots, industrial #sensors, intelligent devices, and #automated devices are the present and the future of modern industries.

Ultimately, it would be difficult for industries to remain competitive in the future without embracing modern industrial automation #technologies.

Photo Credit: IXON Cloud