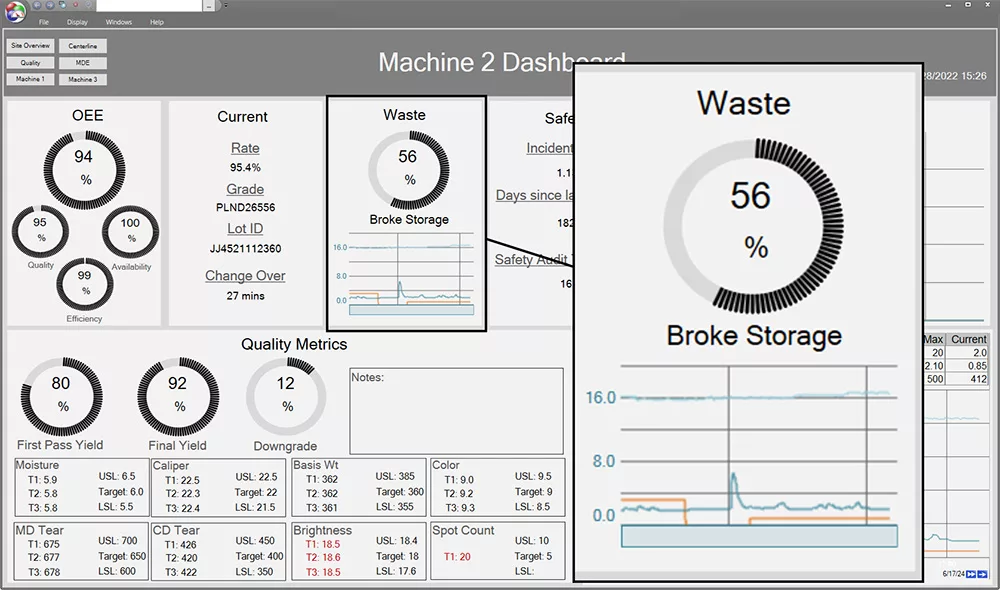

Metrics variables in a Manufacturing Execution System (MES)

Metrics variables in a Manufacturing Execution System (MES) focus on Key Performance Indicators (KPIs) that track, measure, and optimize production efficiency, quality, and equipment effectiveness. To implement industrial data effectively, the MES collects data from equipment and other sources on the factory floor, processes it, and presents actionable insights.

Here’s a breakdown of essential metrics variables and how to implement them within an MES system:

Overall Equipment Effectiveness (OEE):

-

Availability: Measures equipment uptime.

-

Performance: Assesses production speed versus optimal speed.

-

Quality: Tracks the rate of defect-free products.

-

Implementation: Collect data from PLCs, sensors, and production counters to calculate OEE in real-time.

Production Throughput:-

-

Throughput- Measures the number of units produced within a specified period.

-

Implementation: Retrieve data from counters or process signals, updating throughput numbers as items pass key points in the production line.

Cycle Time and Takt Time:

-

Cycle Time: The actual time taken to produce one unit.

-

Takt Time: The rate at which products must be made to meet demand.

-

Implementation: Time stamping events at the start and end of each process, then calculate cycle and takt time by comparing these timestamps.

Downtime and Downtime Reasons:

-

Downtime - Tracks the duration and reasons for equipment stops.

-

Implementation: Connect to HMI/SCADA systems or sensors on machines to monitor for stoppage events, categorize causes, and log data into the MES.

Yield Rate:

-

Yield Rate- Measures the ratio of acceptable product output versus the total output.

-

Implementation: Use quality inspection systems, such as vision systems or manual input, to record defects and calculate yield in the MES.

Scrap and Rework Rate:

-

Scrap and Rework Rate -Tracks the number of defective products that need rework or are scrapped.

-

Implementation: Collect data from inspection stations or quality control checks to identify products that are defective or require rework, and log these events in the MES.

Implementing Industrial Data Collection in MES:

Integration with PLCs and SCADA Systems:

-

Data Collection: Use OPC (Open Platform Communications) or direct connections to pull data from PLCs, SCADA, or sensors into the MES.

-

Implementation: Develop or configure the MES to communicate with shop-floor equipment via protocols like OPC-UA or MQTT to collect real-time production data.

Data Processing and Normalization:

-

Standardize Data: Convert data from various sources into a common format for consistent processing.

-

Implementation: Use middleware or MES modules to normalize data across different equipment types, ensuring accuracy and consistency in reporting.

Database and Storage:

-

Data Management: Store collected data securely for long-term analysis and reporting.

-

Implementation: Use SQL or a cloud-based database to store production data, ensuring accessibility and scalability as data volumes increase.

Analytics and Dashboarding:

-

Visualization: Present data in a user-friendly format to operators, managers, and stakeholders.

-

Implementation: Integrate the MES with dashboarding tools to provide real-time KPI dashboards, historical analysis, and predictive analytics to help make data-driven decisions.

Alarms and Notifications:

-

Automated Alerts: Set thresholds and conditions that trigger alerts.

-

Implementation: Configure the MES to send alerts (e.g., email, SMS) to operators or managers when equipment operates outside predefined limits, enabling quick corrective actions.

However, an MES can provide valuable insights into production operations, enabling better decision-making and continuous improvement in manufacturing. This can be achieved by connecting these metrics and implementation steps.

Image Credit: dataparc