Written by: Edwin Efam Echenim

Abstract

As infrastructure systems continue to age and operational demands intensify, hydro-vacuum excavation and pressure testing have become essential practices for ensuring the integrity and reliability of pipelines and subsurface utilities. This paper examines the transformative potential of digitalization, particularly through the integration of advanced Supervisory Control and Data Acquisition (SCADA) systems and predictive analytics—in optimizing these critical operations. It presents a structured implementation framework, showcases real-world applications, and addresses emerging challenges, including system interoperability, data accuracy, and evolving regulatory requirements.

1. Introduction

Hydro-vacuuming and pressure testing are essential for ensuring the safety and functionality of pipelines, especially in sectors like water management, oil & gas, and utilities. Traditional methods, however, are labor-intensive, reactive, and prone to human error. The integration of digital technologies offers a proactive, data-driven approach that enhances efficiency, safety, and compliance.

2. Future Challenges in Hydro-Vacuuming and Pressure Testing

• Aging Infrastructure: Increasing risk of leaks and failures.

• Manual Testing Limitations: Inconsistent data and delayed response times.

• Regulatory Pressure: Stricter environmental and safety standards.

• Operational Costs: Rising costs of labor, energy, and equipment maintenance.

3. Digitalization as a Solution

3.1 Enhanced Monitoring and Control via SCADA

Real-Time Data Acquisition: SCADA systems continuously monitor pressure, flow, and vacuum strength.

Remote Operation: Operators can manage pumps, valves, and sensors from a centralized interface.

Alarm Systems: Automated alerts for anomalies reduce downtime and prevent accidents.

3.2 Predictive Analytics for Maintenance and Optimization

Leak Detection: Machine learning models analyze pressure decay to detect leaks early.

Equipment Health Monitoring: Predicts failures in pumps and compressors, enabling timely maintenance.

Process Optimization: Adjusts test parameters dynamically to reduce energy use and improve accuracy.

3.3 Integration with Testing Protocols

Automated Test Logging: Ensures traceability and compliance with industry standards.

Digital Twin Simulation: Simulates test scenarios to validate system integrity before execution.

3.4 Safety and Compliance

Regulatory Reporting: Generates detailed, audit-ready reports.

Emergency Response: Real-time data enables rapid intervention during failures.

4. Detailed Implementation Procedure

1. Assessment Phase

Identify critical assets and testing points, evaluate existing infrastructure and data systems.

2. System Design

Select SCADA-compatible sensors and IoT devices and define data architecture and integration points.

3. Deployment

Install sensors and connect to SCADA and configure predictive analytics models using historical and real-time data.

4. Testing and Calibration

Run simulations using digital twins, calibrate sensors and validate model accuracy.

5. Training and Change Management

Train operators and engineers on new systems, establish protocols for data interpretation and response.

6. Monitoring and Optimization

Continuously monitor system performance, refine models and control logic based on feedback.

The code in the link performs a graphical user interface (GUI) application for monitoring and managing a hydro-vacuuming and pressure-testing system. (https://github.com/EchenimEdwin/https-github.com-users-EchenimEdwin-

/blob/main/Hydro%20vacuuming%20and%20pressure%20testing.ipynb)

Here’s a breakdown of what it does

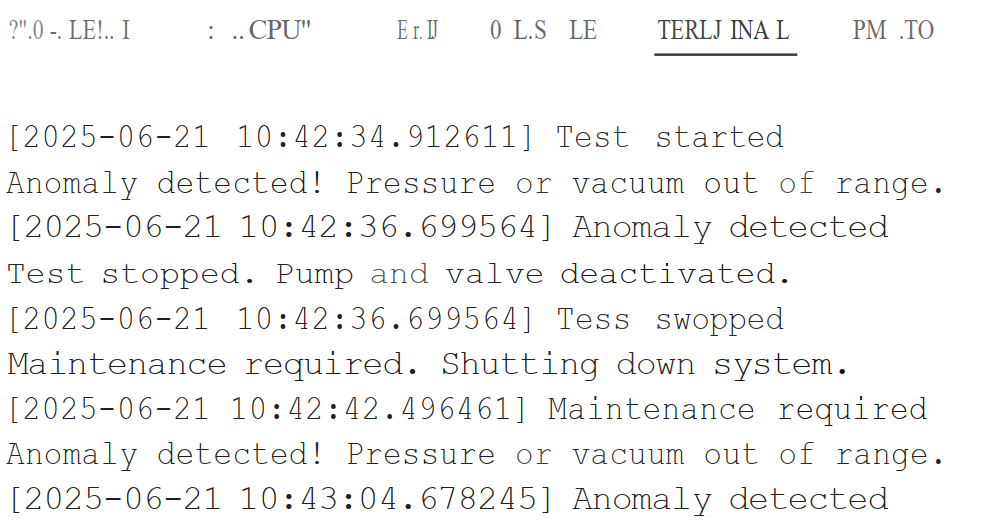

This class simulates the logic of a hydro-vacuum system:

• Initialization: Takes pressure and vacuum thresholds.

• start_test / stop_test / emergency_stop: Simulate starting, stopping, or emergency shutdown of the system.

• monitor_system: Checks if pressure or vacuum readings are within acceptable limits. If not, it logs an anomaly and stops the test.

• predictive_maintenance_check: Simulates a maintenance check and stops the system if maintenance is needed.

• log_event: Logs events with timestamps.

• export_data_to_excel: Saves collected pressure/vacuum data to an Excel file.

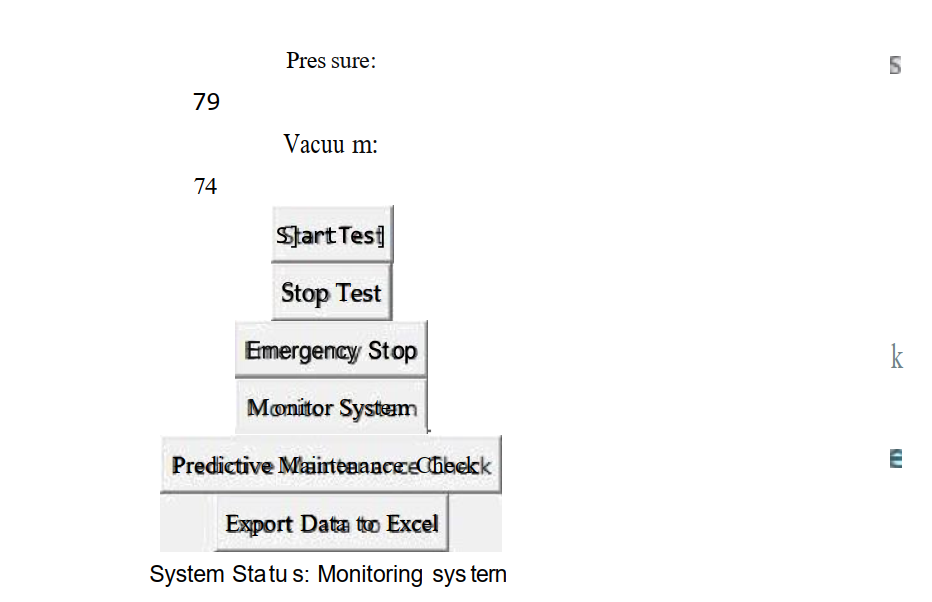

This class builds the GUI using tkinter:

• Input Fields: For entering pressure and vacuum values.

• Buttons: To start/stop tests, trigger emergency stop, monitor the system, check for maintenance, and export data.

• Status Label: Displays current system status.

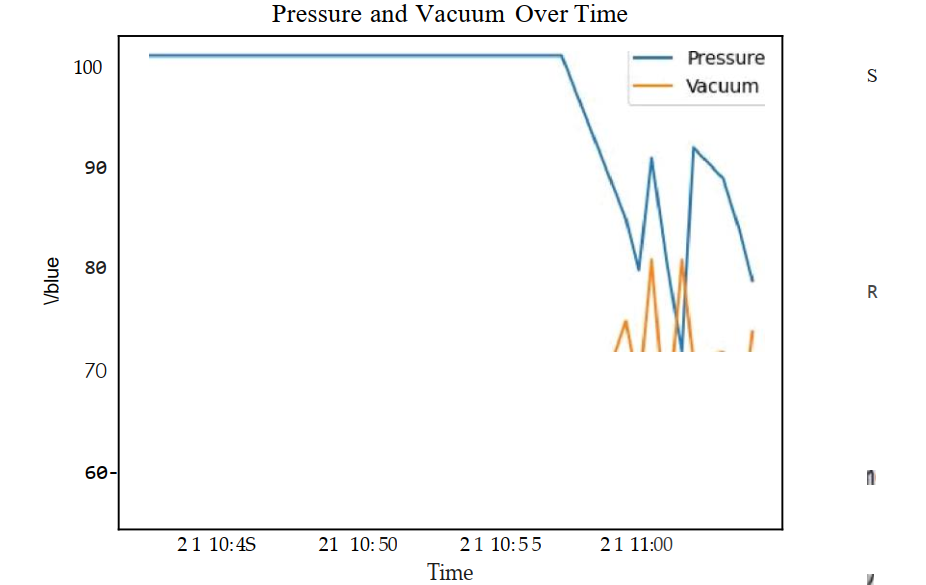

• Plotting: Uses matplotlib to plot pressure and vacuum over time.

The programming generates a tracking procedure for hydro- vacuum control system: GUI Application Overview, with the graphical representation below.

5. Use Case: Oil & Gas Pipeline Commissioning

In an oil & gas pipeline commissioning:

SCADA monitors pressure during pipeline testing.

Predictive analytics identifies weak sections before failure.

Vacuum strength is adjusted based on soil conditions.

All data is logged for future planning and regulatory audits.

6. Conclusion

Digitalization through SCADA and predictive analytics offers a transformative solution to the challenges of hydro-vacuuming and pressure testing. By enabling real-time monitoring, predictive maintenance, and automated compliance, these technologies not only improve operational efficiency but also future-proof infrastructure systems against growing demands and regulatory scrutiny.

References

[1] Hussain Al-Sadah, ‘SCADA Systems Outlook amid Industry 4.0’, Saudi Aramco, 2025.

[2] ‘Predictive Maintenance in SCADA-Based Industries: A Literature Review’, International Journal of Industrial Engineering and Engineering Management, 2025.

[3] ‘SCADA AI Integration Across Different Sectors in 2025’, Industry Report, 2025.

[4] Siemens, ‘Digitalization of Energy Systems – Siemens White Paper’, 2025.

[5] Schneider Electric, ‘One Digital Grid Platform’, 2025.