Introduction

In industrial control panel design, safety, compliance, and system reliability are all influenced by one key factor—circuit type. Before selecting protection devices such as circuit breakers or supplementary protectors, it is essential to understand the type of circuit in use.

There are three primary circuit types relevant to control panels: feeder, motor branch, and control circuits. Each type has specific protection requirements defined by UL and NEC standards. Applying the correct protection device based on circuit type is not only a best practice—it’s a compliance requirement.

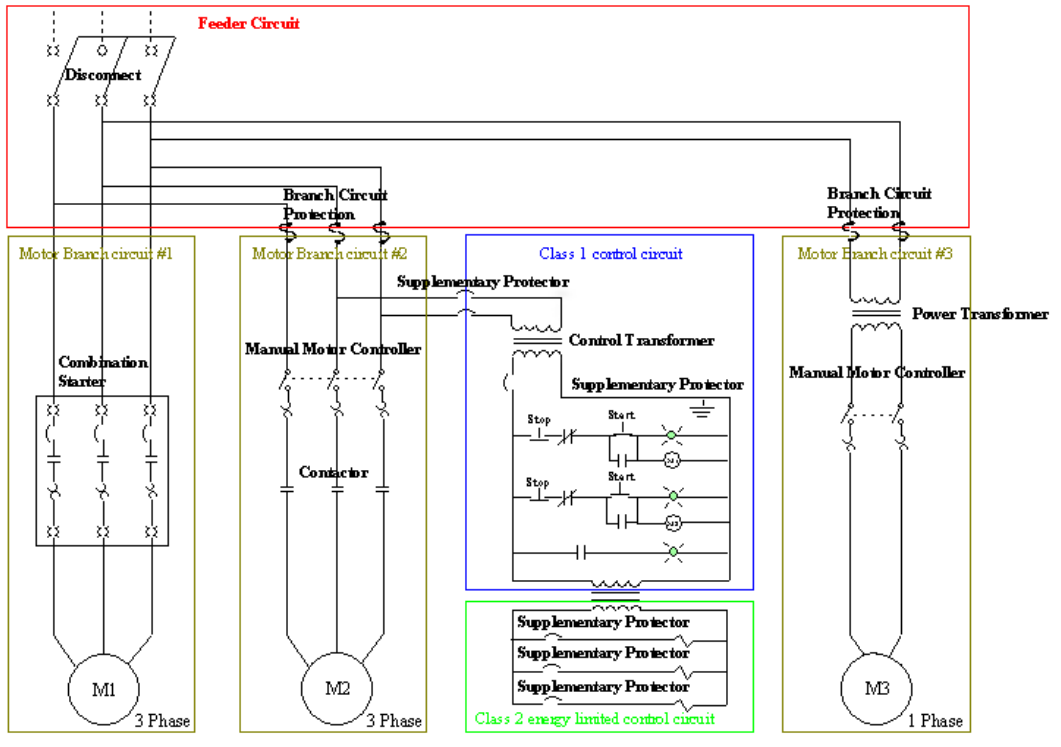

1. Feeder Circuits in Control Panels

Feeder circuits deliver power from the main distribution panel to the control panel or between panels within an industrial system.

Protection Considerations:

- UL 489 circuit breakers or fuses are mandatory.

- Devices must handle high interrupting ratings and protect against both overloads and short circuits.

- Serve as the primary protection for downstream equipment and branch circuits.

Use in Panels:

- Powering internal distribution blocks or multiple sub-circuits

- Main disconnect protection

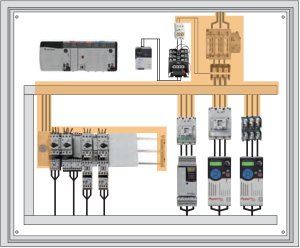

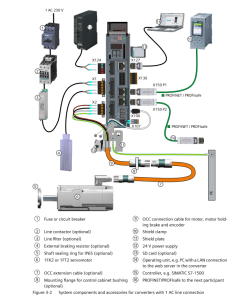

2. Motor Branch Circuits

Motor branch circuits provide power directly to motors or motor control devices inside the control panel.

Protection Considerations:

- Must tolerate motor inrush current during startup.

- Require coordinated protection per NEC Article 430.

- Should prevent nuisance tripping while ensuring short-circuit and overload protection.

Applicable Devices:

- UL 489 motor circuit protectors (MCPs)

- Manual motor protectors (MMPs)

- Self-protected combination motor controllers

Use in Panels:

Protection for motor starters, variable frequency drives (VFDs), and motor contactors

Can be integrated into combination starters

3. Control Circuits

Control circuits operate at lower voltages and control the logic, signaling, and actuation of devices within the control panel.

a. Class 1 Control Circuits (up to 600V)

- May be powered by control transformers or directly from a branch circuit

- Require protection using UL 489 or UL 1077 devices based on configuration

- Higher energy levels than Class 2; stricter protection standards apply

Panel Application:

- Control relays,

- contactor coils,

- solenoid valves, and

- other command/control elements

b. Class 2 Control Circuits (energy-limited to 30V/100VA)

- Regulated by NEC Article 725

- Considered inherently safe due to their limited power

- May use supplementary protectors (UL 1077)

- Ideal for low-voltage I/O, sensors, and instrumentation circuits

Panel Application:

- PLC I/O,

- safety sensors,

- HMI interfaces, and

- low-voltage signaling

Why It Matters in Panel Design

Choosing protection based on circuit type is essential in industrial control panel design because:

✅ UL and NEC Compliance: Ensures certification and safety inspection approvals

✅ Component Protection: Prevents premature equipment failure and operational downtime

✅ System Coordination: Supports selective tripping and reduces system-wide interruptions

✅ Reliability: Enhances lifecycle performance of the entire control panel system

Conclusion

In industrial control panels, not all circuits are created equal. Whether you’re powering a 3-phase motor or protecting a 24V DC sensor loop, the circuit type dictates the protection strategy.

By understanding the role of feeder, motor branch, and control circuits—and applying UL 489 or UL 1077 devices accordingly—you build safer, more efficient, and standards-compliant panels. For complex applications, consult with manufacturers or certified control panel builders to make informed protection decisions.