Introduction

In electrical design, choosing the right protection matters. It affects safety, performance, and compliance. Two key standards in North America are UL 489 and UL 1077. They are often confused, but they serve very different roles. Picking the correct one is crucial for protecting equipment and ensuring system reliability.

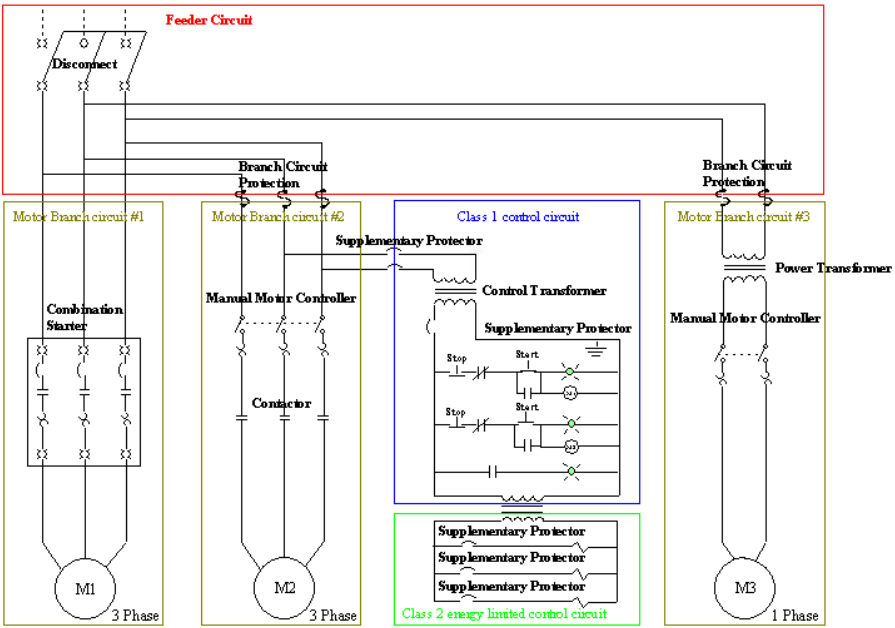

UL 489 – Branch Circuit Protection

UL 489 applies to molded-case circuit breakers. These breakers protect branch circuits. They are tested rigorously. Tests include calibration, overload, endurance, and short-circuit performance.

UL 489 breakers are designed to interrupt high fault currents. They are required by the NEC in most applications.

Key Features

- High interrupt rating

- Long-term durability

- Suitable for feeder and branch circuits

- Used in industrial, commercial, and institutional systems

- They are the main protection in most power distribution designs.

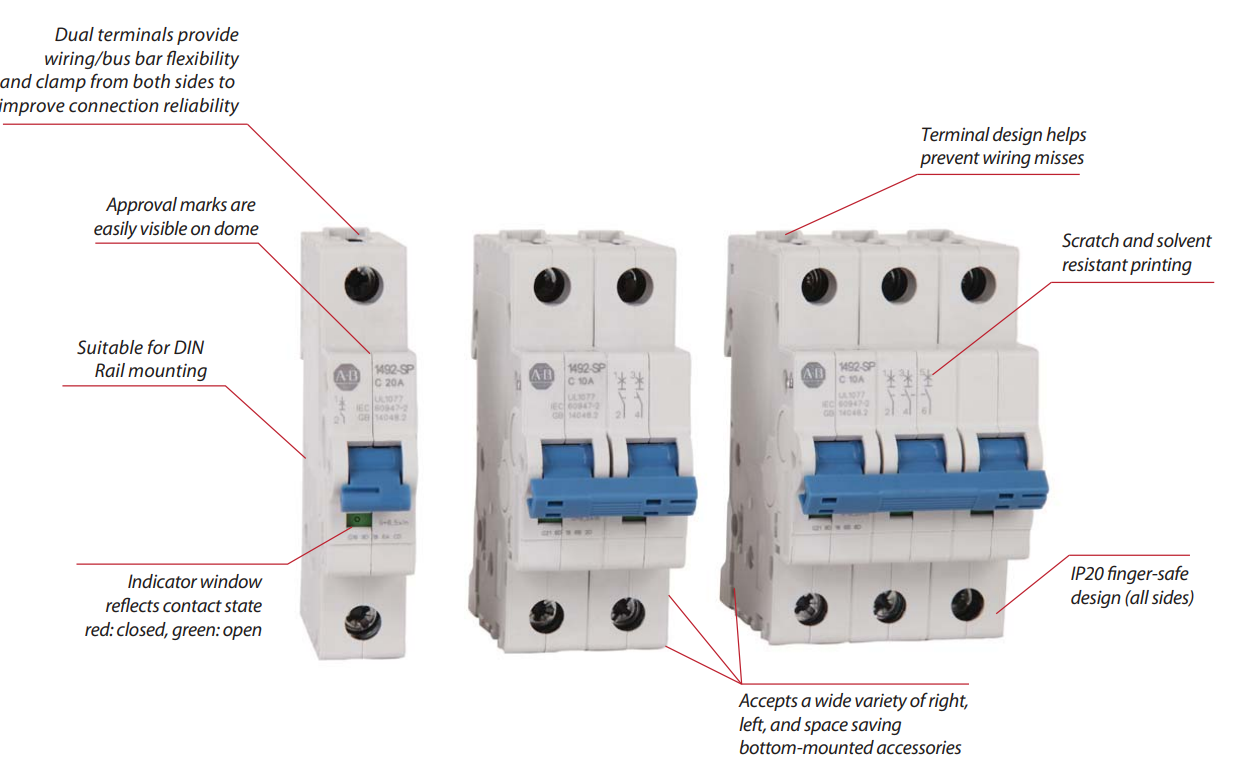

UL 1077 – Supplementary Protection

UL 1077 applies to supplementary protectors. These are not for branch circuits. Instead, they offer extra protection inside already protected systems.

UL 1077 devices are smaller and more cost-effective. They’re used in control panels, PLCs, or low-voltage equipment.

Key Features

- Not for primary circuit protection

- Lower interrupt capacity

- Used after a UL 489 breaker or fuse

- Common in OEM equipment and internal panel circuits

- They are ideal when you only need to protect individual components.

Choosing Between UL 489 and UL 1077

- The choice depends on your application.

- If the device must handle fault current directly from the power source, use UL 489.

- If the circuit is already protected and you need extra protection for a specific component, UL 1077 may be used.

- Never use UL 1077 devices as primary protection.

Conclusion

UL 489 and UL 1077 serve different purposes. UL 489 breakers are for main overcurrent protection. UL 1077 protectors are for internal or supplementary roles. Knowing the difference ensures safety, compliance, and better design. When unsure, consult a qualified engineer or device supplier. Choose wisely to protect your panel and your people.

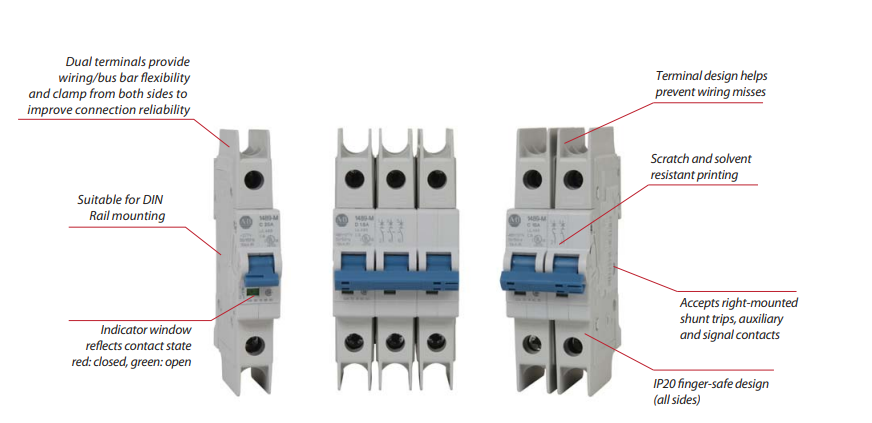

Image credit: Rockwell Automation