Modern industrial automation demands motion systems that are not only high-performance, but also tightly integrated, scalable, and safe. Kinetix® Integrated Motion, part of the Rockwell Automation® Integrated Architecture®, delivers a unified approach to motion control that simplifies machine design, commissioning, operation, and long-term maintenance.

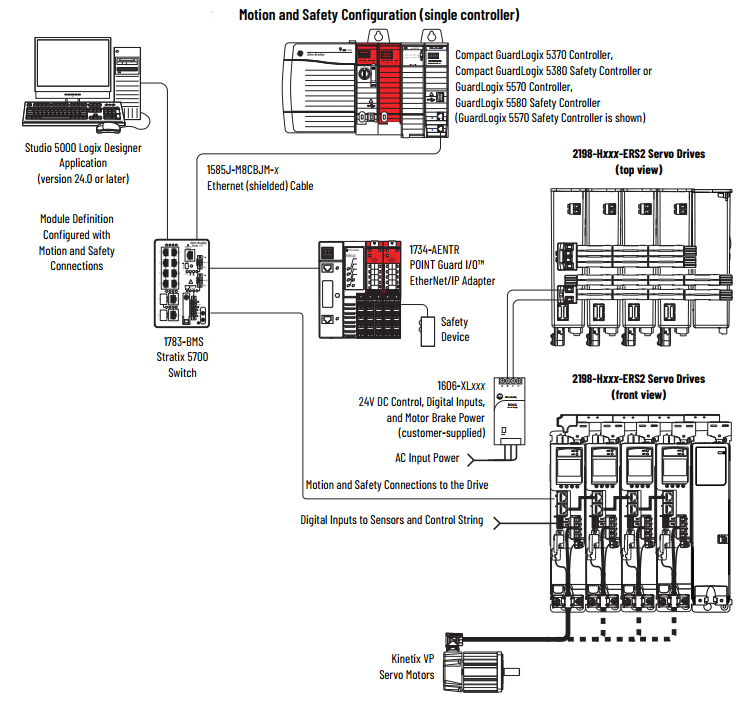

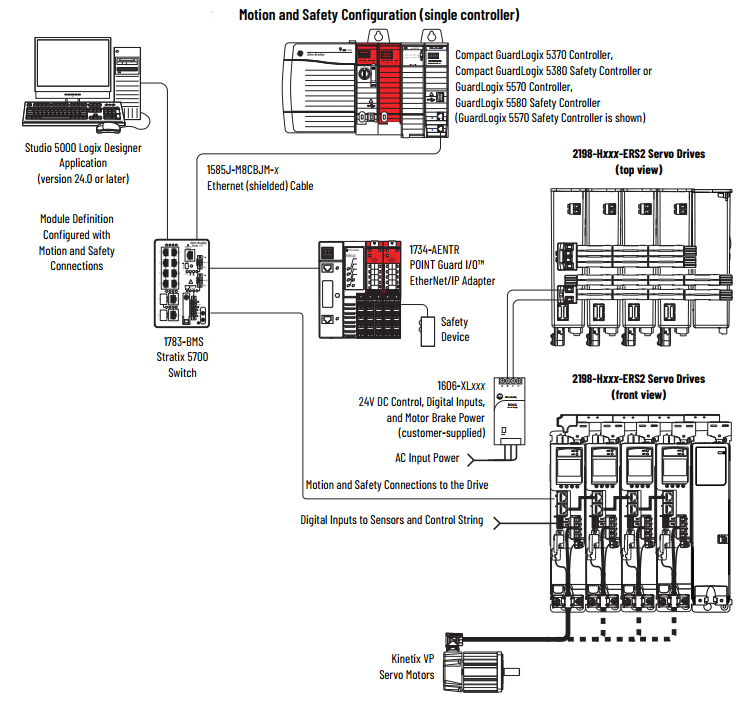

By integrating motion directly into RSLogix 5000 software and the Studio 5000 Logix Designer application, Kinetix Integrated Motion enables engineers to configure, program, and maintain motion systems within a single development environment.

Kinetix Integrated Motion operates over a standard EtherNet/IP™ network using CIP Motion™, CIP Sync™, and CIP Safety™ technologies from ODVA. Built on the Common Industrial Protocol (CIP™), this architecture ensures global interoperability, consistent performance, and seamless device integration.

Time synchronization across drives, I/O, and other EtherNet/IP-compliant devices allows precise coordination of motion, enabling engineers to solve complex applications while improving plant-wide visibility, real-time control, and operational efficiency.

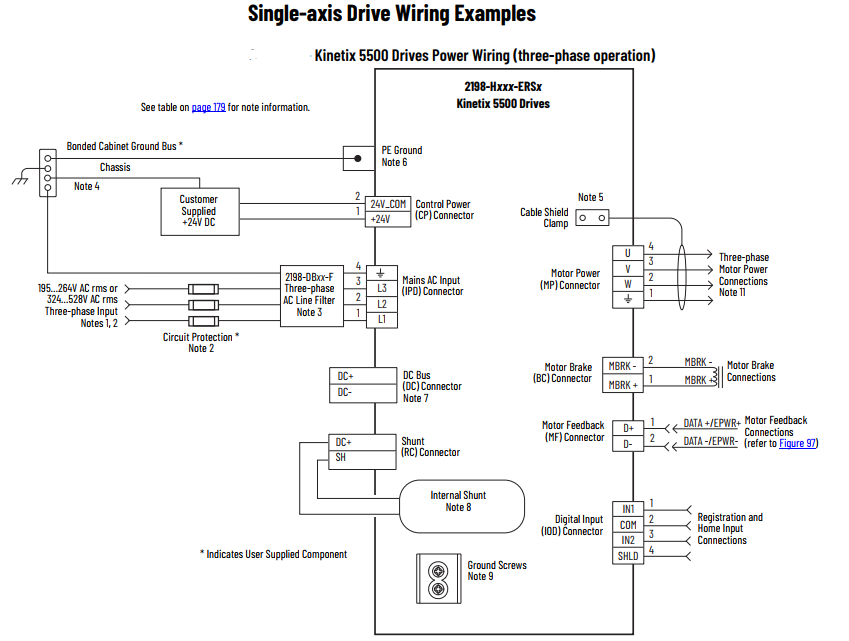

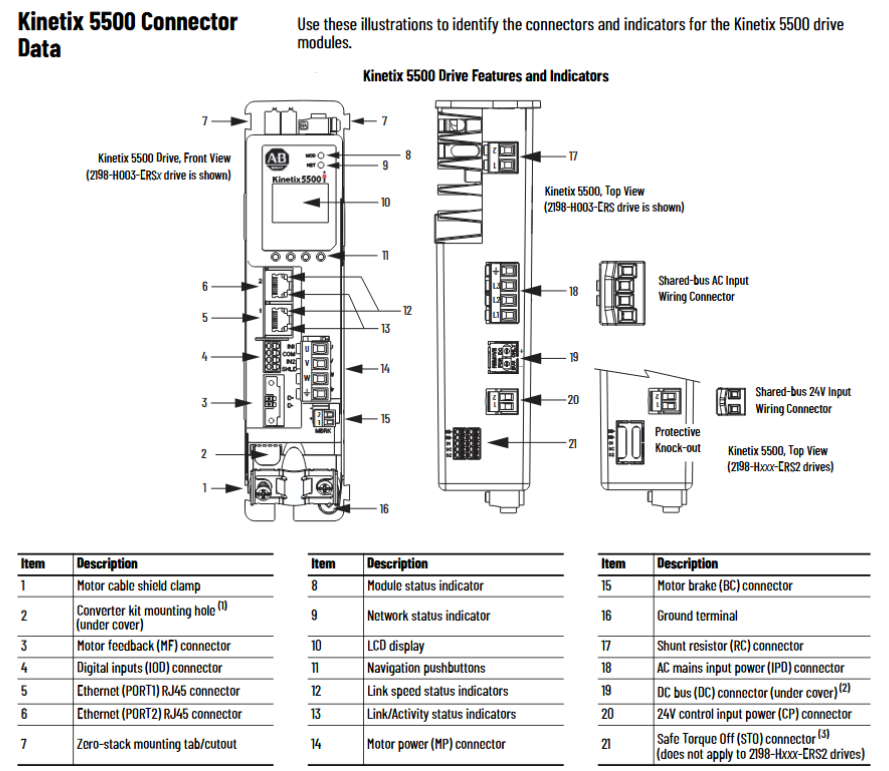

The Kinetix 5500 servo drives are designed to deliver a flexible and scalable motion solution within the Kinetix Integrated Motion platform. These drives support both 200V and 400V-class systems, operating in single-phase or three-phase configurations.

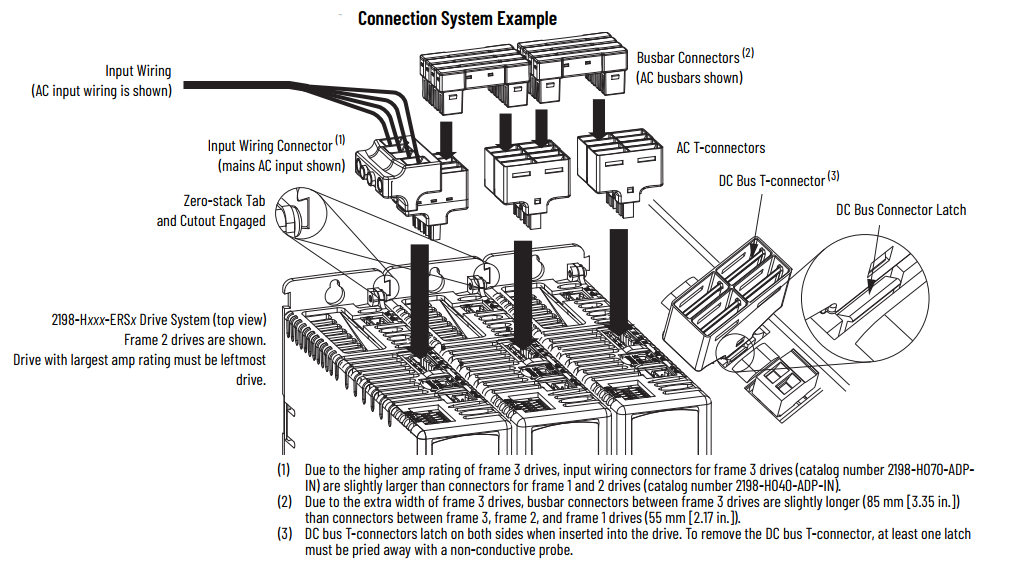

They can be deployed in standalone applications or expanded into multi-axis systems using shared-bus power architectures. The zero-stacked, drive-to-drive design minimizes panel space while simplifying power distribution across axes.

Kinetix 5500 drives support multiple system topologies to accommodate different machine and plant requirements:

Single-phase or three-phase operation

Ideal for independent axis control

Three-phase AC and 24V control power shared across multiple drives

All drives must have the same power rating

AC input power, 24V control power, and DC bus shared

Suitable for compact multi-axis systems

A leader drive supplies DC power to follower drives

Leader drive power rating must be equal to or greater than follower drives

Parallel converter drives increase DC-bus capacity

Converter drive ratings must match and exceed inverter drive ratings

These options provide engineers with significant flexibility when designing scalable multi-axis motion systems.

Kinetix 5500 servo drives are available with Safe Torque Off (STO) to help meet functional safety requirements:

Hardwired STO using dedicated safety connectors

Network-integrated STO over EtherNet/IP™ (available on 2198-Hxxx-ERS2 models)

This flexibility allows safety integration to align with machine architecture and safety standards.

The Kinetix 5500 platform supports a wide range of motors and actuators, making it suitable for diverse motion applications.

Kinetix VP series: VPL, VPF, VPH, VPS (200V and 400V)

Kinetix MP series: MPL, MPM, MPF, MPS

Requires Hiperface-to-DSL feedback converter kit

Kinetix VPAR linear actuators

Kinetix MPAS ballscrew actuators

MPAR and MPAI linear actuators

Kinetix LDAT linear motors (with feedback converter)

Supported in open-loop frequency control applications

All Kinetix 5500 motion configuration, programming, commissioning, and maintenance are performed in Studio 5000 Logix Designer®.

Version 21.00 or later supports CompactLogix® and ControlLogix® controllers

Version 24.00 or later is required for 2198-Hxxx-ERS2 servo drives

This unified engineering environment reduces development time and simplifies long-term system support.

Kinetix 5500 drives require 24V DC control power for internal circuitry. Due to shared-bus architectures and varying current demands, careful evaluation of control power is essential.

Key considerations include:

Ensuring the 24V DC power supply can support the total system current

Using separate 24V power supplies for high-demand bus groups when necessary

Maintaining input voltage within 24V ±10% (21.6–26.4V DC)

To minimize voltage drop:

Mount the 24V power supply close to the drive system

Use larger wire gauges where required (up to 10 mm² / 6 AWG with shared-bus connections)

Kinetix 5500 servo drives support linear, ring, and star Ethernet topologies. They integrate seamlessly with CompactLogix®, ControlLogix®, and GuardLogix® controllers, enabling reliable real-time motion control over EtherNet/IP™.

The combination of Kinetix® Integrated Motion and Kinetix 5500 servo drives provides a powerful, flexible, and scalable motion control platform. By unifying motion, safety, and networking within Studio 5000® and EtherNet/IP™, this solution supports high-performance machine design while simplifying commissioning, maintenance, and future expansion.

For engineers building modern automation systems, the Kinetix 5500 remains a proven and adaptable choice within Rockwell Automation’s Integrated Architecture®.

Reference: Rockwell Automation Publication 2198-UM001N-EN-P – September 2024